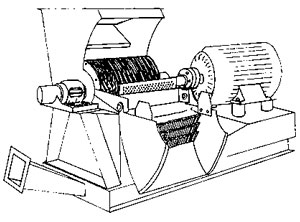

Feed hammer mill

Feed hammer mill also called feed grinding machine can be divided into wide chamber feed hammer mill, A-series feed hammer mill and waterdrop feed hammer mill, which avaiable,mostly used for fine grinding and widely used in animal feed pellet plant or aquatic and poultry feed production. install in the animal feed pellet production line.

Feed hammer mill is a necessary equipment in animal feed pellet plant. We supply three types of feed hammer mills, this one is called common feed hammer mill mainly used for grinding grain products that are to be made into livestock feed pellets or poultry feed pellets.

Application of feed grinding machine

1.The aquatic feed hammer mill is widely adopted in large and medium scale aquatic or poultry feed pellet manufacturing industries. It’s a pretreatment equipment to cut down the size of the feed raw materials with a water content of 8%-13% for further processing. As a fine grinding machine, its grinding fineness can reach 50 mesh. The common raw materials for the aquatic feed hammer mill are grains such as wheat, maize, rice, soybean, groundnut, millet or other solid materials such as bone, dry meat and so on.

2.The poultry feed hammer mill is mainly used in large and medium scale animal feed manufacturing industries and food processing enterprise. It can be used for both general grinding and fine grinding. Equipped with the removable sieve tooth plates, the poultry feed hammer mill is available for different fineness requirements of the feed material.

3.Feed hammer mill is specially designed for feed raw materials general crushing. It is mostly suitable for livestock or poultry feed pellet factories and food processing enterprise. The raw materials are easy to obtain: corn, maize, wheat bran, rice, sorghum, millet, yam, beans, leftover etc. The water content limit of the raw materials is 8-14%.

Remarkable Features of Feed Hammer Mill

1. The all-in-one base design makes the structure of the feed hammer mill very steady.

2. Universal type product, stable performance, widely used for grinding of raw materials in large and medium-sized animal and aquatic feed processing factories.

2. Not only ordinary grinding but also fine grinding are available, mostly used for fine grinding.

3. Fineness of the finished products can reach over 50 mesh.

4. Adopt coupling direct drive, scientific and reasonable hammer arrangement and hammer screen clearance ensure uniform fineness of the finished products.

5. Advanced twice strike technology of the pulverizing chamber, good rigidity pedestal and small vibration.

6. Equipped with imported high quality SKF bearings, good performance, low working temperature.

7. A variety of sieve sizes are available to choose, flexible opening device and elastic pressure sieve mechanism, convenient to operate and maintain.

8. Siemens motor

Feed hammer mill or feed grinding machine has some requirements

1. Overload is strictly forbidden.

2. Avoid hard sundries material feeding into the crushing chamber to damage the hammer plates.

3. After the machine work 1000 hours, the bearing need a unpick and wash, adding the grease at the same time. Prevent dust from entering the bearing.

4. Correctly install the hammers and to weigh them regularly. Change the hammers with a weight less than the stated weight.

Correctly install the sieves, the rough side should toward inside to install.

6. Keep clear of the air outlet.

Feed hammer mill is one of main parts for fish feed pellet machine, we can sale the animal feed production line and sale them alone. welcome to inquiry them.The next procees is producing feed pellets by flat Die Animal Feed Pellet Making Machine or Ring Die Animal Feed Pellet Mill.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel FREE to contact us!